Crafting a Custom Bathroom Vanity: A Step-by-Step Guide

A bathroom vanity serves as a focal point and functional storage solution within a bathroom. While pre-fabricated vanities are readily available, constructing a custom vanity offers advantages such as tailored dimensions, personalized design aesthetics, and potential cost savings. Undertaking a DIY bathroom vanity project requires careful planning, precise execution, and a foundational understanding of carpentry principles. This article outlines the key steps involved in building a custom bathroom vanity, emphasizing accuracy and attention to detail throughout the process.

Planning and Design Considerations

The initial phase of building a custom bathroom vanity involves meticulous planning and design. This stage dictates the final aesthetics, functionality, and structural integrity of the vanity. Measurement accuracy is paramount, as it directly impacts the fit and overall appearance of the finished product.

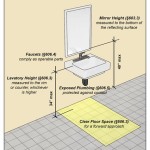

First, precisely measure the available space within the bathroom where the vanity will be installed. Consider the placement of existing plumbing fixtures, such as water supply lines and drain pipes. Note the height of the current countertop, or determine a comfortable and ergonomic height for the new vanity. Industry standards often recommend a vanity height of around 30 to 36 inches, but individual preferences should be factored in.

Next, choose a style that complements the bathroom's existing decor. Options range from traditional raised-panel designs to modern, minimalist styles. Consider the desired storage capacity and configuration. Drawers, cabinets, or a combination of both can be incorporated. Sketch out different design ideas, paying attention to overall proportions and aesthetic balance.

Once the design is finalized, create a detailed construction plan. This plan should include precise measurements for all components, including the cabinet box, doors, drawer faces, and countertop. A cut list is essential for minimizing material waste and ensuring accurate cuts. The plan should also specify the type of wood, hardware, and finishing materials to be used.

Choosing the appropriate materials is critical for both the functionality and longevity of the vanity. Hardwoods, such as maple, oak, and cherry, are durable and resistant to moisture, making them suitable for bathroom environments. Softwoods, such as pine, are more affordable but may require additional sealing and protection. Plywood or MDF (Medium-Density Fiberboard) can be used for the cabinet box, providing a stable and cost-effective substrate.

Hardware selection is equally important. Choose high-quality hinges, drawer slides, and knobs or pulls that complement the design. Consider soft-close hinges and drawer slides for added convenience and to prevent slamming. Stainless steel or brass hardware is resistant to corrosion and ideal for humid bathroom conditions.

Construction Process: Building the Vanity Cabinet

The construction phase involves assembling the cabinet box, installing drawers and doors, and preparing the vanity for finishing. Accurate cuts, secure joinery, and careful attention to detail are crucial for creating a durable and aesthetically pleasing vanity.

Begin by cutting all the components according to the cut list. Use a table saw, circular saw, or miter saw to ensure accurate and square cuts. Label each piece to avoid confusion during assembly. Construct the cabinet box using screws, nails, or wood glue. Pocket hole joinery is a popular and effective method for assembling cabinet boxes, providing strong and concealed joints. Ensure all corners are square and that the frame is level.

Install the face frame, if the design includes one. The face frame adds structural support and provides a finished appearance. Attach the face frame to the cabinet box using wood glue and nails or screws. Ensure that the face frame is flush with the cabinet box and that all joints are tight. Reinforce the joints with wood clamps while the glue dries.

Construct the drawers using plywood or solid wood. Dado joints or rabbet joints are commonly used for drawer construction, providing strong and durable connections. Assemble the drawer boxes using wood glue and nails or screws. Install the drawer slides according to the manufacturer's instructions. Ensure that the drawer slides are properly aligned so that the drawers operate smoothly.

Build the doors using solid wood or plywood. Raised-panel doors can be created using a router and specialized router bits. Flat-panel doors are simpler to construct, requiring only accurate cuts and assembly. Install the hinges on the doors and cabinet box. Ensure that the doors are properly aligned and that they swing freely. Use shims if necessary to adjust the door alignment.

Once the cabinet box, drawers, and doors are assembled, sand all surfaces smooth. Start with a coarse-grit sandpaper and gradually move to finer grits. Pay particular attention to edges and corners, rounding them slightly to prevent chipping. Remove all sanding dust with a tack cloth or vacuum cleaner.

Finishing and Installation

The finishing stage involves applying a protective coating to the wood to enhance its appearance and protect it from moisture. Proper preparation and application techniques are essential for achieving a durable and professional-looking finish. Installation involves securing the vanity in place, connecting the plumbing, and installing the countertop.

Apply a primer to the wood to seal the pores and provide a base for the topcoat. Choose a primer that is compatible with the type of wood and the desired finish. Apply the primer evenly using a brush, roller, or sprayer. Allow the primer to dry completely according to the manufacturer's instructions. Sand the primer lightly with fine-grit sandpaper to create a smooth surface for the topcoat.

Apply the topcoat, which can be paint, stain, or varnish. Choose a finish that is durable and resistant to moisture. Apply the topcoat evenly using a brush, roller, or sprayer. Apply multiple thin coats, allowing each coat to dry completely before applying the next. Sand lightly between coats to create a smooth and even finish.

Install the countertop, which can be made of granite, marble, quartz, or laminate. Apply a bead of silicone caulk to the top of the cabinet box to create a waterproof seal. Carefully place the countertop on the cabinet box, ensuring that it is properly aligned. Secure the countertop to the cabinet box using screws or construction adhesive.

Connect the plumbing fixtures, including the faucet, drain, and water supply lines. Follow the manufacturer's instructions for installing the plumbing fixtures. Ensure that all connections are tight and leak-free. Wrap the threads of pipe fittings with Teflon tape to prevent leaks.

Install the hardware, including the knobs or pulls on the doors and drawers. Choose hardware that complements the design of the vanity. Ensure that the hardware is securely attached. Make any necessary adjustments to the doors and drawers to ensure that they operate smoothly and properly. Finally, caulk any gaps between the vanity and the wall or floor to prevent moisture damage.

Build Your Own Bathroom Vanity Fine Homebuilding

:max_bytes(150000):strip_icc()/build-something-diy-vanity-594402125f9b58d58ae21158.jpg?strip=all)

16 Diy Bathroom Vanity Plans You Can Build Today

How To Build Your Own Bathroom Vanity Fine Homebuilding

How To Build Your Own Bathroom Vanity Fine Homebuilding

How To Build A Diy Bathroom Vanity Angela Marie Made

Diy Bathroom Vanity 12 Rehabs Bob Vila

Diy Open Shelf Vanity With Free Plans

10 Diy Bathroom Vanity Ideas The Family Handyman

How To Build A 60 Diy Bathroom Vanity From Scratch

How To Build A Diy Bathroom Vanity Angela Marie Made

Related Posts