Understanding Proper Bathroom Sink Plumbing

Bathroom sink plumbing is a fundamental aspect of residential and commercial infrastructure. A properly installed and maintained plumbing system ensures efficient water supply and drainage, prevents leaks and water damage, and contributes to the overall functionality and hygiene of the bathroom. This article aims to provide a comprehensive understanding of the components, principles, and best practices involved in bathroom sink plumbing.

A standard bathroom sink plumbing system comprises several interconnected parts, each serving a specific purpose. These include the water supply lines, shut-off valves, faucet, drain assembly, P-trap, and drainpipe. Understanding the function of each component is crucial for effective installation, troubleshooting, and repair.

The water supply lines, typically made of copper, PEX (cross-linked polyethylene), or flexible braided stainless steel, deliver hot and cold water to the faucet. Shut-off valves, located on the supply lines beneath the sink, allow for isolating the water supply for maintenance or repairs without shutting off the water to the entire building. The faucet controls the flow and temperature of the water dispensed into the sink basin. The drain assembly, consisting of the sink strainer, tailpiece, and pop-up drain mechanism, collects wastewater from the sink and directs it into the drainage system.

The P-trap, a U-shaped pipe located beneath the sink, is a critical component that prevents sewer gases from entering the bathroom. It works by trapping a small amount of water, which acts as a barrier against these noxious and potentially harmful gases. Finally, the drainpipe connects the P-trap to the main drain line, carrying wastewater away from the sink and into the sewer system.

Key Point 1: Essential Components and Their Functions

A successful bathroom sink plumbing installation hinges on understanding the role of each individual component and ensuring its proper connection within the system. Neglecting any part can lead to performance issues, leaks, or even significant water damage.

The water supply lines are the lifelines of the sink, delivering water under pressure. The material choice for these lines affects their longevity and resistance to corrosion. Copper is a traditional choice, known for its durability, but requires soldering for connections. PEX is a flexible alternative that uses compression fittings, simplifying installation. Braided stainless steel supply lines offer flexibility and are resistant to bursting, making them a popular choice for replacements.

Shut-off valves are essential for maintenance and emergency situations. These valves allow the water supply to be cut off directly at the sink, preventing the need to shut off the water to the entire house or building. There are two main types: straight stops and angle stops. Straight stops are used when the supply line comes directly out of the wall, while angle stops are used when the supply line comes out at an angle.

The faucet is more than just a water dispenser; it is a key aesthetic element of the bathroom. Faucets come in various styles, including single-handle, double-handle, and widespread. The choice of faucet should consider both functionality and design. Ensure the faucet is compatible with the sink's hole configuration before installation.

The drain assembly is responsible for efficiently removing wastewater from the sink. The sink strainer prevents debris from entering the drainpipe, reducing the risk of clogs. The tailpiece connects the strainer to the P-trap. The pop-up drain mechanism allows for easy opening and closing of the drain, typically controlled by a lever located near the faucet.

The P-trap is arguably the most important component of the drain system. Its U-shape creates a water seal that prevents sewer gases from backing up into the bathroom. Regular cleaning of the P-trap is recommended to remove any accumulated debris and maintain its functionality. A blocked P-trap can lead to slow drainage and unpleasant odors.

The drainpipe connects the P-trap to the main drain line, carrying wastewater away. This pipe is typically made of PVC or ABS plastic. Proper sealing and connection of the drainpipe are crucial to prevent leaks. Use appropriate pipe sealant or Teflon tape on threaded connections to ensure a watertight seal.

Key Point 2: Installation and Best Practices

Proper installation is paramount to ensuring a leak-free and functional bathroom sink plumbing system. Following best practices during installation minimizes the risk of future problems and extends the lifespan of the plumbing components.

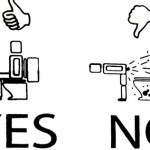

Before beginning any plumbing work, it is essential to shut off the water supply at the shut-off valves. If shut-off valves are not present or are malfunctioning, the main water supply to the building must be turned off. This prevents uncontrolled water flow and potential water damage during the installation process.

When connecting water supply lines, ensure that the connections are tight but not overtightened. Overtightening can damage the fittings and lead to leaks. Use two wrenches – one to hold the fitting and the other to tighten the connection – to prevent twisting and potential damage to the pipes.

Proper alignment of the drain assembly is crucial for leak-free operation. Ensure that all components are properly seated and aligned before tightening the connections. Use plumber's putty or silicone sealant to create a watertight seal between the sink strainer and the sink basin.

The P-trap should be installed with a slight slope towards the drainpipe to facilitate proper drainage. Ensure that the P-trap is securely connected to both the tailpiece and the drainpipe. Hand-tighten slip nuts initially and then use a wrench to tighten them further, but avoid overtightening.

When connecting PVC or ABS drainpipes, use appropriate primer and cement. Apply primer to both the inside of the fitting and the outside of the pipe, then apply cement and quickly join the two pieces. Hold the connection firmly for a few seconds to allow the cement to set. Ensure that the connection is leak-free before concealing the pipes.

Always test the plumbing system for leaks after installation. Turn on the water supply and check all connections for any signs of water leakage. Tighten any connections as needed to eliminate leaks. Run water into the sink and check the drainpipe and P-trap for leaks as well. If leaks persist, disassemble the connections and re-seal or replace the faulty components.

Key Point 3: Troubleshooting Common Plumbing Problems

Even with proper installation, bathroom sink plumbing systems can experience problems over time. Understanding common issues and how to troubleshoot them can save time and money on repairs.

One of the most common problems is a clogged drain. This can be caused by hair, soap scum, or other debris accumulating in the drainpipe or P-trap. A plunger can often dislodge minor clogs. For more stubborn clogs, a drain snake or auger can be used to break up or remove the blockage.

Leaks are another frequent issue. Leaks can occur at any connection point in the plumbing system. Carefully inspect all connections, including supply lines, shut-off valves, faucet connections, drain assembly, and P-trap connections, to identify the source of the leak. Tighten loose connections or replace worn-out washers or O-rings.

Slow drainage can indicate a partial blockage in the drainpipe or P-trap. Remove and clean the P-trap to remove any accumulated debris. If the slow drainage persists, use a drain snake to clear any blockages further down the drainpipe.

Low water pressure can be caused by a variety of factors, including clogged aerators, faulty shut-off valves, or issues with the main water supply. Clean or replace the aerator on the faucet to improve water flow. Check the shut-off valves to ensure they are fully open. If the problem persists, consult a qualified plumber to investigate potential issues with the main water supply.

Unpleasant odors emanating from the drain can indicate a dry P-trap or a buildup of bacteria in the drainpipe. Ensure that the P-trap contains water by running the faucet for a few minutes. Clean the drainpipe with a solution of baking soda and vinegar to eliminate odors.

Gurgling sounds coming from the drain can indicate a venting problem in the plumbing system. This can be caused by a blocked vent pipe, which prevents proper air circulation in the drain system. Consult a qualified plumber to inspect and clear any blockages in the vent pipe.

Addressing plumbing issues promptly can prevent further damage and more costly repairs. Regular maintenance and periodic inspections can help identify potential problems before they escalate.

How To Plumb A Bathroom With Multiple Plumbing Diagrams Hammerpedia

Bathroom Sink Plumbing

How To Install Bathroom Sink Drain Queen Bee Of Honey Dos

What Is The Bathroom Sink Plumbing Rough In Heights

How To Plumb A Bathroom With Multiple Plumbing Diagrams Hammerpedia

How To Fit A Bathroom Sink Diy Guides Victorian Plumbing

How To Vent A Toilet Sink And Shower Drain

4 Ways To Seal A Sink Drain Pipe

The 10 Most Common Plumbing Mistakes Diyers Make

How To Plumb A Bathroom With Multiple Plumbing Diagrams Hammerpedia

Related Posts