Crafting a Unique and Durable Bathroom Sink with DIY Cement

A DIY cement bathroom sink is an excellent project for those seeking a unique, stylish, and cost-effective solution for their bathroom. Cement offers a versatile and adaptable material, allowing you to shape and design the sink according to your desired aesthetic. This article will guide you through the process of creating your own cement sink, covering the necessary materials, tools, and steps for a successful project.

Choosing Materials and Tools

The success of your DIY cement sink hinges upon selecting the right materials and tools. Begin by acquiring the following:

- Portland cement: This is the primary ingredient for the concrete mix.

- Sand: Provides texture and helps with workability of the mix.

- Aggregate (gravel or crushed stone): Adds strength and durability to the concrete.

- Water: Used to activate the cement and create a workable concrete mix.

- Plastic sheeting: Protects your workspace and creates a mold for the sink.

- Wood planks or plywood: Used for building the mold's frame and ensuring its stability.

- Silicone sealant: Seals the mold for a smooth and clean finish.

- Mixing containers and tools: Buckets, trowels, and a mixer for preparing the concrete mix.

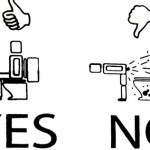

- Gloves and safety glasses: Protect your hands and eyes from the concrete mix.

Once you have gathered the necessary materials and tools, you are ready to create your own unique cement bathroom sink.

Molding the Concrete Sink

Creating the mold for your sink is a crucial step in the DIY process. You can choose from a variety of mold designs, ranging from simple rectangular shapes to more intricate curves and forms. The mold serves as the foundation for your sink, dictating its final shape and dimensions.

To create the mold, follow these steps:

- Design the mold: Decide on the shape and dimensions of your sink. Consider its placement in your bathroom and the desired size and depth.

- Construct the frame: Build the mold's frame using wood planks or plywood. Ensure that the frame is sturdy and capable of supporting the weight of the concrete mix.

- Apply silicone sealant: Seal the edges of the mold with silicone sealant to prevent concrete from leaking out and create a smooth finish for the sink.

- Line the interior: Line the mold's interior with plastic sheeting to create a non-stick surface that will allow you to easily remove the finished sink.

The mold is now ready to receive the concrete mix.

Mixing and Pouring the Concrete

The consistency of the concrete mix plays a vital role in the final outcome of your sink. A well-mixed concrete mix will ensure a smooth and durable finish. To mix the concrete, follow these guidelines:

- Mix the dry ingredients: Combine the Portland cement, sand, and aggregate in a mixing container. Ensure that the dry ingredients are well-distributed and there are no lumps.

- Add water slowly: Gradually add water to the dry ingredients while mixing thoroughly. Begin with a small amount of water and increase it as needed to achieve a workable consistency.

- Check the consistency: The ideal consistency should be thick enough to retain its shape when scooped, but not too dry to be difficult to work with.

- Pour into the mold: Carefully pour the concrete mix into the prepared mold, ensuring that it fills all corners and crevices.

- Level the surface: Use a trowel to level the surface of the concrete mix and remove any air bubbles.

After pouring the concrete, allow it to cure for at least 24 hours to gain sufficient strength.

Sink Concrete Bathroom Diy

How S It Holding Up Diy Concrete Vanity Update

How To Create Poured Concrete Vanity Tops And Shower Curbs Content Co

Vanity Top Made From Concrete Diy For Less Uncookie Cutter

Diy Concrete Sink Countertop Ll Small Bathroom Renovation

Diy Concrete Vanity Heather Bullard

Concrete And Wood Sink Drawing Diy Crafts Bathroom Countertops

Concrete Sink Tutorial Countertop Experts

Diy Concrete Sink

Diy Concrete Counter Overlay Vanity Makeover

Related Posts