How to Make a Wooden Bathroom Countertop

A wooden bathroom countertop can introduce warmth and character to a space often dominated by tile and porcelain. While seemingly straightforward, constructing a durable and aesthetically pleasing wooden countertop requires careful planning, selection of appropriate materials, and precise execution. This article details the process of creating a wooden bathroom countertop, encompassing material choices, fabrication techniques, and essential finishing procedures to ensure longevity and resistance to moisture.

Selecting the Right Wood Species

The selection of wood species is paramount for a bathroom countertop due to the humid environment. The chosen wood must possess inherent resistance to moisture, dimensional stability to minimize warping or cracking, and a visual appeal that aligns with the bathroom's overall design. Certain hardwoods and some carefully treated softwoods are typically considered.

Hardwoods generally offer superior durability and water resistance compared to softwoods. Popular choices include:

- Teak: Renowned for its exceptional water resistance due to its natural oils, teak is a premium option. Its density and tight grain structure make it highly resistant to rot and decay. However, teak can be a more expensive choice.

- Walnut: A beautiful hardwood with a rich, dark color, walnut provides a sophisticated aesthetic. While not as naturally water-resistant as teak, walnut can be effectively sealed and protected with appropriate finishes.

- Maple: Maple is a light-colored hardwood known for its hardness and durability. It accepts finishes well and can be stained to match various design schemes. Its closed-grain structure helps minimize water absorption.

- White Oak: Unlike red oak, white oak possesses closed pores, making it more resistant to water penetration. It is a strong and durable wood that can be stained or finished naturally.

- Ipe: This exotic hardwood is incredibly dense and strong, making it exceptionally water-resistant and durable. Ipe is often used for decking and outdoor furniture, making it a suitable option for high-moisture environments. However, working with Ipe can be challenging due to its hardness.

Softwoods can also be used, but they require meticulous sealing and finishing. Options include:

- Cedar: Naturally resistant to decay and insects, cedar emits a pleasant aroma. However, it is softer than most hardwoods and more prone to scratches and dents.

- Cypress: Similar to cedar, cypress is naturally water-resistant. It is a relatively soft wood, so careful sealing and finishing are essential.

Regardless of the wood species chosen, it is crucial to kiln-dry the wood thoroughly to reduce its moisture content. This minimizes the risk of warping, cupping, or cracking after installation. The ideal moisture content for wood used in bathrooms is typically between 6% and 8%.

Fabrication Process: From Rough Lumber to Countertop Slab

The fabrication process involves several stages, from selecting and preparing the lumber to assembling and shaping the countertop. Each step requires precision to ensure a structurally sound and visually appealing final product.

1. Lumber Selection and Preparation:

Begin by selecting lumber that is free of defects, such as knots, cracks, and excessive sapwood. Choose boards that are slightly wider and longer than the desired finished dimensions of the countertop. This allows for trimming and shaping.

2. Milling and Jointing:

Milling the lumber involves flattening one face using a jointer. This creates a reference surface for дальнейшей machining. Then, flatten the opposite face using a planer, bringing the boards to a consistent thickness. Next, joint one edge of each board to create a perfectly straight edge for gluing.

3. Gluing Up the Slab:

Arrange the boards in the desired order, paying attention to grain direction and color variations. Apply glue evenly to the jointed edges and clamp the boards together tightly. Use sufficient clamping pressure to ensure a strong and seamless joint. Allow the glue to dry completely, following the manufacturer's recommendations.

4. Flattening and Sanding:

Once the glue is dry, remove the clamps and flatten the assembled slab using a planer or a wide-belt sander. Ensure that the surface is perfectly flat and smooth. Progress through progressively finer grits of sandpaper, typically starting with 80-grit and ending with 220-grit, to achieve a smooth and even surface.

5. Shaping and Edge Profiling:

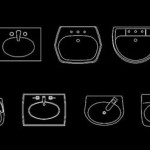

Use a router with various edge profiles to shape the edges of the countertop. Options include bullnose, ogee, and chamfered edges. Ensure that the edges are smooth and consistent. Alternatively, leave the edges square for a more modern look. At this stage, cut out any necessary holes for sinks or faucets, using appropriate hole saws or routers.

6. Sealing and Finishing (Detailed in the next section):

This is the crucial step to protect the wood from moisture damage. Applying multiple coats of a suitable sealant and finish is essential for ensuring longevity.

Sealing and Finishing for Moisture Protection

The finishing process is arguably the most critical aspect of creating a wooden bathroom countertop. It involves selecting and applying sealants and finishes that will protect the wood from moisture, stains, and everyday wear and tear. The finish must be durable, water-resistant, and aesthetically pleasing.

1. Sanding to a Fine Grit:

Before applying any finish, ensure the countertop is sanded to a very fine grit, typically 220-grit or higher. This creates a smooth and consistent surface for the finish to adhere to. Remove all sanding dust with a tack cloth or vacuum cleaner.

2. Sealing the Wood:

The first step is to seal the wood to prevent water penetration. Several options are available:

- Epoxy Resin: Offers excellent water resistance and durability. It creates a thick, impervious layer that protects the wood from moisture. Epoxy resin is particularly suitable for countertops that will be exposed to frequent water contact.

- Penetrating Epoxy Sealers: These sealers penetrate deep into the wood fibers, hardening them and making them more water-resistant. They are a good option for woods that are not naturally water-resistant.

- Marine-Grade Varnish: Formulated for use on boats, marine varnish provides excellent water resistance and UV protection. It is a durable and long-lasting finish that can withstand harsh conditions.

Apply the sealant according to the manufacturer's instructions, ensuring complete and even coverage. Allow the sealant to dry thoroughly before proceeding to the next step.

3. Applying the Finish:

Once the sealant has dried, apply a topcoat finish to provide additional protection and enhance the appearance of the countertop. Several options are available:

- Polyurethane: A durable and water-resistant finish that is available in various sheens, from matte to high-gloss. Polyurethane is a popular choice for bathroom countertops due to its durability and ease of application. Oil-based polyurethanes tend to be more durable.

- Spar Urethane: Similar to marine varnish, Spar Urethane offers excellent water resistance and flexibility, making it suitable for environments with fluctuating humidity.

- Conversion Varnish: A two-part finish that offers exceptional durability and chemical resistance. It is a more advanced finish that requires specialized equipment and knowledge to apply.

- Waterlox: A tung oil-based finish that penetrates deep into the wood, providing excellent water resistance and a natural look. It is easy to apply and maintain.

Apply multiple thin coats of the finish, allowing each coat to dry completely before applying the next. Sand lightly between coats with fine-grit sandpaper (320-grit or higher) to create a smooth and even surface. Follow the manufacturer's instructions for drying times and application methods.

4. Curing the Finish:

After applying the final coat of finish, allow the countertop to cure completely before using it. Curing times vary depending on the type of finish used, but typically range from several days to several weeks. During the curing process, the finish hardens and becomes more resistant to scratches and stains.

5. Regular Maintenance:

Even with a durable finish, regular maintenance is essential to prolong the life of a wooden bathroom countertop. Wipe up spills immediately and avoid using abrasive cleaners or harsh chemicals. Apply a furniture polish or wax periodically to protect the finish and maintain its luster. Reapply the finish every few years as needed to maintain its water resistance and durability, depending on frequency of use and exposure to water.

By carefully selecting the right wood species, employing proper fabrication techniques, and applying a durable and water-resistant finish, a wooden bathroom countertop can be a beautiful and functional addition to any bathroom. Regular maintenance will ensure its longevity and preserve its aesthetic appeal for years to come.

How To Build Protect A Wood Vanity Top Houseful Of Handmade

Diy Vanity Tops For Your Bathroom

How To Make A Wooden Vanity Top Countertop

How To Build Diy Wood Countertops In A Day Wooden Bathroom Vanity Countertop

Diy Bathroom Countertop Made From Cedar Fence Boards Addicted 2 Decorating

How To Build Protect A Wood Vanity Top Houseful Of Handmade

Wood Countertops In Bathrooms Centsational Style

How To Build Protect A Wood Vanity Top Houseful Of Handmade

Rustic Bathroom Vanity Kreg Tool

Diy Wood Bathroom Countertop An Easy Way To Change Your Vanity In 1 Weekend Noting Grace