Make Your Own Bathroom Sink

Creating a custom bathroom sink can be a rewarding project for those with some DIY experience and an eye for design. A handcrafted sink can add a unique touch to your bathroom, allowing you to incorporate specific materials and designs you desire. This article will guide you through the process of making your own bathroom sink, covering key steps and considerations for a successful project.

Choosing the Right Material

The first step is selecting the material for your sink. Various options offer distinct characteristics and aesthetics. Some of the most popular materials for custom bathroom sinks include:

- Concrete: Concrete is a durable and versatile material for bathroom sinks. It can be molded into various shapes and sizes and finished with different textures and colors.

- Stone: Natural stone, such as granite, marble, or limestone, adds elegance and sophistication to a bathroom. Stone sinks are known for their durability and unique patterns.

- Wood: Wooden sinks offer a warm and rustic appeal. They are often made from hardwoods like teak or mahogany, known for their water resistance.

- Resin: Resin is a versatile material that can be cast in various shapes and colors. It is often used for creating unique and customizable sink designs.

- Metal: Metals like copper or stainless steel can create modern and industrial-looking sinks. These materials are durable and can be polished to a high shine.

Consider the desired aesthetics, durability, and maintenance requirements when choosing the material.

Designing and Molding

The next step is designing the sink's shape and size. You can sketch your desired design or use computer-aided design (CAD) software to create a detailed blueprint. Consider the following factors during the design process:

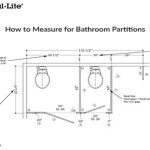

- Size and Shape: The sink's size should be appropriate for the bathroom's space and the anticipated use. Consider the size of the countertop and the overall layout.

- Depth: The depth of the sink bowl will affect how much water it can hold and its overall appearance.

- Drain Location: Determine the location of the drain hole for proper water flow.

- Overflow Hole: Consider adding an overflow hole to prevent water from spilling over the edges.

Once you have finalized the design, you can start molding the sink. Depending on the chosen material, you might need to use a mold made from silicone, fiberglass, or other materials. Ensure the mold is strong enough to withstand the weight and pressure of the material you are using.

Crafting and Finishing

After molding, you can begin crafting the sink. The process varies depending on the chosen material. For concrete sinks, you will need to mix the concrete according to the manufacturer's instructions and pour it into the mold. For stone sinks, you will likely need to carve and shape the stone.

Once the sink has hardened or cured, you can sand down the surface and apply a sealant to protect it from water damage and staining. You can also use a variety of finishing techniques - such as painting, staining, or polishing - to achieve the desired look.

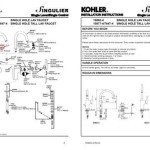

Installing the Sink

When the sink is fully completed, you can install it in the bathroom. The installation process can vary depending on the type of countertop and the sink's design. You might need to cut a hole in the countertop to accommodate the sink.

Remember to use appropriate tools and materials for the installation process. Consult a professional if you are unsure about any of the steps.

Safety and Precautions

Crafting a bathroom sink involves working with potentially hazardous materials and tools. Observe proper safety precautions during the entire process, which includes:

- Wear protective gear: Wear appropriate safety glasses, gloves, and respiratory protection to protect your eyes, skin, and lungs from dust and fumes.

- Use proper tools: Use tools designed for the specific tasks and materials you are working with.

- Follow material instructions: Carefully read and follow the manufacturer's instructions for all materials used.

- Work in a well-ventilated area: Ensure adequate ventilation to prevent the buildup of fumes.

- Be aware of potential hazards: Be cautious of sharp edges, heavy objects, and potential chemical exposures.

Safety should be the top priority throughout the project. By following these guidelines and being cautious, you can minimize risks and enjoy a safe DIY experience.

Build Your Own Bathroom Vanity Fine Homebuilding

Diy Bathroom Vanity 12 Rehabs Bob Vila

:max_bytes(150000):strip_icc()/build-something-diy-vanity-594402125f9b58d58ae21158.jpg?strip=all)

16 Diy Bathroom Vanity Plans You Can Build Today

13 Crazy Creative Diy Bathroom Vanities Decoist

Diy Bathroom Vanity 12 Rehabs Bob Vila

10 Diy Bathroom Vanity Ideas The Family Handyman

10 Diy Bathroom Vanity Ideas The Family Handyman

Diy Wood Vanity In The Master Bathroom Space Between

Diy Bathroom Vanity 12 Rehabs Bob Vila

How To Build Your Own Bathroom Vanity Fine Homebuilding

Related Posts