Determining the Appropriate Water Line Size for a Bathroom

Selecting the correct water line size for a bathroom is a crucial step in plumbing design and installation. Insufficient water line diameter can lead to pressure drops, reduced flow rates, and compromised fixture performance. Conversely, unnecessarily large pipes can increase material costs and potentially lead to water stagnation in low-use applications. A well-informed decision ensures efficient water delivery, minimizes the risk of future plumbing issues, and complies with local building codes.

The primary factors influencing water line size selection involve analyzing the anticipated water demand within the bathroom, understanding the relationship between pipe diameter and flow rate, and considering the impact of pipe material and length on overall system performance. A comprehensive approach necessitates a thorough evaluation of fixture types, simultaneous usage patterns, and the specific characteristics of the plumbing system.

Evaluating Fixture Demand and Simultaneous Use

Accurately assessing the water demand of each fixture within the bathroom is a fundamental prerequisite to determining the appropriate water line size. Fixtures such as toilets, showers, bathtubs, and sinks exhibit varying flow rate requirements, typically expressed in gallons per minute (GPM). These requirements are often specified by the fixture manufacturer and are generally outlined in plumbing codes. Consult the fixture specifications to ascertain the minimum acceptable flow rate for optimal performance.

The concept of "fixture units" is often incorporated in plumbing codes to simplify the process of calculating total water demand. A fixture unit represents a standardized measure of the water demand of a particular fixture. Different fixture types are assigned different fixture unit values. For instance, a typical toilet may be assigned a value of 5 fixture units, while a lavatory faucet might be assigned 1 or 2 fixture units. The precise values may vary slightly depending on the local plumbing code.

Simultaneous use, the scenario where multiple fixtures are operated concurrently, plays a critical role in determining the peak water demand. It is highly improbable that all fixtures in a bathroom will be utilized at their maximum flow rates simultaneously. Therefore, plumbing codes typically incorporate a demand factor to account for the statistical probability of simultaneous usage. This factor reduces the overall design flow rate, preventing over-sizing of the water lines. To determine the correct water line size, it is necessary to calculate the total fixture units for the bathroom and then apply the appropriate demand factor as specified in the local plumbing code. This adjusted value then informs the appropriate pipe diameter.

For example, consider a bathroom with the following fixtures: a toilet (5 fixture units), a shower (2 fixture units), and a lavatory faucet (1 fixture unit). The total fixture units for this bathroom are 8. Consulting the plumbing code's demand factor table corresponding to 8 fixture units might reveal a demand factor of, for instance, 0.6. Applying this factor to the total fixture units yields a design flow rate proportional to 4.8 fixture units. This value is used to determine the appropriate pipe diameter from a plumbing sizing chart.

Understanding Pipe Diameter, Flow Rate, and Pressure Drop

The relationship between pipe diameter, flow rate, and pressure drop is governed by fundamental principles of fluid mechanics. A smaller pipe diameter increases water velocity for a given flow rate, leading to a larger pressure drop due to increased friction against the pipe walls. Conversely, a larger pipe diameter reduces water velocity, resulting in a lower pressure drop. Maintaining adequate water pressure at all fixtures is essential for proper operation. Insufficient pressure can manifest as weak shower streams, slow toilet refills, and reduced faucet flow.

The Hazen-Williams formula and similar equations are frequently used in plumbing design to calculate pressure drop in pipes. These formulas take into account factors such as pipe diameter, pipe length, flow rate, and a roughness coefficient that depends on the pipe material. While these equations can be applied manually, various software tools and online calculators are available to simplify the process.

Acceptable pressure drop values are typically specified in plumbing codes. Exceeding the allowable pressure drop can lead to inadequate performance, while minimizing pressure drop often necessitates larger, more expensive piping. A balance must be struck between the cost of materials and the desired level of performance. Plumbers often target a maximum pressure drop of 5 to 8 pounds per square inch (PSI) per 100 feet of pipe. This provides a reasonable balance between performance and material costs.

For typical residential bathrooms, a ½-inch copper or PEX pipe is often sufficient for the hot and cold water supply lines to individual fixtures. However, a ¾-inch pipe may be necessary for the main supply line to the bathroom, especially if the bathroom is located far from the main water supply or if multiple fixtures are used simultaneously. In situations with low water pressure from the municipal supply, a larger pipe size may be needed to compensate.

When transitioning between different pipe sizes, it's essential to adhere to best practices to minimize turbulence and pressure loss. Utilize gradual transitions rather than abrupt changes in diameter. Avoid sharp bends and excessive fittings, as these can also contribute to pressure drop. Proper installation techniques are crucial to ensure optimal system performance.

Considering Pipe Material, Length, and Local Code Requirements

The material used for water lines significantly impacts their hydraulic characteristics and overall system performance. Copper, PEX (cross-linked polyethylene), and CPVC (chlorinated polyvinyl chloride) are commonly used materials, each possessing distinct advantages and disadvantages. Copper offers durability and resistance to corrosion but tends to be more expensive than PEX or CPVC. PEX provides flexibility, ease of installation, and resistance to freezing. CPVC is often used for hot water lines due to its high-temperature resistance. The roughness coefficient in the Hazen-Williams formula varies depending on the material, influencing the calculated pressure drop. Selecting the appropriate material depends on factors such as cost, durability, ease of installation, and compatibility with local plumbing codes.

The length of the water lines exerts a direct influence on the total pressure drop within the system. Longer pipe runs result in greater frictional losses. Therefore, it is crucial to minimize pipe lengths whenever possible and to strategically locate fixtures to reduce the distance between the water source and the point of use. Consider using a manifold system, where a central distribution point provides separate lines to each fixture. This approach can significantly reduce pressure loss compared to a traditional trunk-and-branch system where water flows through a series of interconnected pipes.

Local plumbing codes establish the minimum standards for water line sizing and installation. These codes are designed to ensure public health and safety and to promote efficient water usage. Plumbing codes often specify minimum pipe diameters for various fixtures and dictate the methods for calculating water demand and pressure drop. Consult the local plumbing code or a qualified plumbing professional to ensure compliance with all applicable regulations. Failure to adhere to these codes can result in costly rework and potential safety hazards.

Furthermore, the water quality in the area can influence the choice of pipe material. In areas with acidic water, copper pipes may be susceptible to corrosion. In such cases, PEX or CPVC may be a more suitable alternative. Conducting a water quality test can help identify potential issues and inform the selection of the most appropriate pipe material.

Proper support and insulation of water lines are also essential considerations. Support hangers should be installed at appropriate intervals to prevent sagging and stress on the pipes. Insulation helps to prevent heat loss from hot water lines and reduces the risk of freezing in cold climates. Installing insulation also minimizes condensation on cold water lines, preventing potential water damage.

Ultimately, determining the appropriate water line size for a bathroom requires a thorough understanding of fixture demand, pipe hydraulics, material properties, and local code requirements. While DIY installations may be tempting, it is generally advisable to consult with a licensed plumbing professional to ensure that the system is designed and installed correctly. A qualified plumber can accurately assess the specific needs of the bathroom, select the appropriate pipe sizes and materials, and ensure compliance with all applicable regulations. This approach will minimize the risk of future plumbing problems and ensure optimal performance of the bathroom fixtures.

Domestic Water Piping Design Guide How To Size And Select

Pipes And Home Plumbing For Diy Plumbers

:strip_icc()/SCP_173_04-a5f887244add47e48d7a24d0579341d7.jpg?strip=all)

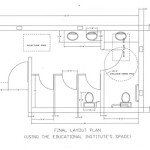

The Ultimate Guide To Bathroom Plumbing Diagrams And Layouts

Have The Correct Water Supply Line Size 3 Factors

Domestic Water Piping Design Guide How To Size And Select

How To Size Your Water Lines Pex Or Copper Williams Plumbing

Toilet Rough In The 4 Dimensions You Need To Know Hammerpedia

What Size Pipe For Shower Supply Head Sizes

Toilet Supply Line What Is It And Does Do Toiletology

Domestic Water Piping Design Guide How To Size And Select

Related Posts