Bathroom Vanity: Exploring the "No Holes" Option

The bathroom vanity serves as a crucial element in bathroom design, providing storage, counter space, and aesthetic appeal. When selecting a vanity, homeowners face a multitude of choices regarding style, size, material, and features. One specific consideration gaining traction is the "no holes" bathroom vanity. This design refers to vanities specifically manufactured without pre-drilled faucet holes in the countertop. This configuration presents both advantages and disadvantages that warrant careful examination before making a purchase decision.

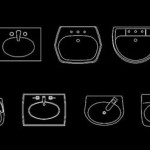

The absence of pre-drilled holes allows for greater flexibility in faucet selection and placement. Traditional vanities typically come with either one or three holes, accommodating specific faucet configurations like single-hole or widespread faucets. However, the "no holes" vanity offers complete freedom to choose any faucet style and position it precisely according to personal preference and design requirements. This adaptability can be particularly valuable in achieving a customized or minimalist bathroom aesthetic.

Conversely, the installation process for a "no holes" vanity requires additional steps. Since the holes are not pre-drilled, the homeowner or installer must carefully measure and drill the necessary openings to accommodate the chosen faucet. This process demands precision and the use of appropriate tools to avoid damaging the countertop material. Furthermore, an under-mount sink is typically required for "no holes" vanity installations, which may add to the overall cost and complexity of the project.

Key Point 1: Faucet Selection and Design Flexibility

The primary benefit of a "no holes" bathroom vanity lies in its ability to offer unparalleled design flexibility. With traditional vanities, faucet selection is often dictated by the existing hole configuration. A three-hole vanity, for example, necessitates the use of a widespread faucet, limiting the options for those who prefer a single-hole or wall-mounted faucet design. The "no holes" approach eliminates this restriction, empowering homeowners to select any faucet style that aligns with their vision.

This flexibility extends beyond the faucet style itself. The absence of pre-drilled holes allows for precise placement of the faucet on the countertop. This is particularly beneficial when trying to achieve a specific aesthetic, such as a minimalist or asymmetrical design. The faucet can be positioned to optimize water flow, ergonomics, or visual balance within the bathroom space. This level of customization is simply not possible with vanities that have fixed hole configurations.

Moreover, "no holes" vanities offer increased design flexibility when pairing them with unique sink designs. Vessel sinks, which sit atop the countertop rather than being recessed, are particularly well-suited for "no holes" vanities. The absence of pre-drilled holes allows for a clean, uncluttered look that complements the vessel sink's elevated profile. Wall-mounted faucets are also a popular choice for "no holes" vanities, as they eliminate the need for any holes in the countertop altogether, creating a sleek and modern aesthetic.

Consider a scenario where a homeowner desires a modern bathroom with a vessel sink and a single-handle faucet positioned slightly off-center. A traditional vanity with pre-drilled holes would immediately present a significant obstacle, as the existing holes would dictate the faucet placement and likely interfere with the desired aesthetic. A "no holes" vanity, on the other hand, provides a blank canvas upon which the homeowner can realize their vision without compromise.

Key Point 2: Installation Considerations and Challenges

While the design flexibility of "no holes" vanities is undeniable, the installation process presents certain challenges that must be carefully considered. The absence of pre-drilled holes means that the homeowner or installer is responsible for drilling the necessary openings to accommodate the chosen faucet and drain assembly. This requires careful planning, precise measurements, and the use of appropriate power tools.

The first step in the installation process involves determining the optimal placement of the faucet. This requires careful consideration of the sink dimensions, the faucet reach, and the desired ergonomic factors. Once the ideal location has been identified, the installer must precisely mark the drilling points on the countertop. It is crucial to use accurate measuring tools and a level to ensure that the holes are drilled in the correct position and orientation.

The next step involves selecting the appropriate drill bits for the countertop material. Different countertop materials, such as granite, marble, quartz, or solid surface, require specialized drill bits to prevent chipping, cracking, or other damage. It is essential to consult with a knowledgeable professional or refer to the manufacturer's instructions to determine the correct type of drill bit for the specific countertop material. Drilling through natural stone often requires wet drilling techniques to prevent overheating and damage to the stone.

The drilling process itself demands patience and precision. It is generally recommended to start with a pilot hole using a smaller drill bit, followed by progressively larger drill bits until the desired hole size is achieved. Applying consistent pressure and maintaining a steady hand are crucial to ensure a clean and accurate hole. Rushing the process or using excessive force can result in damage to the countertop, requiring costly repairs or replacement.

Furthermore, proper sealing of the drilled holes is essential to prevent water damage and maintain the integrity of the countertop. A high-quality sealant should be applied around the faucet and drain assembly to create a watertight barrier. Regular inspection and maintenance of the sealant are necessary to ensure its continued effectiveness over time.

Key Point 3: Cost Implications and Sink Compatibility

The decision to opt for a "no holes" bathroom vanity can have implications for the overall cost of the bathroom renovation project. While the vanity itself may not be significantly more expensive than a traditional vanity, the additional installation costs and the potential need for specialized tools can add to the overall expense.

As previously mentioned, the installation of a "no holes" vanity requires specialized knowledge and skills. Homeowners who are not comfortable with DIY projects may need to hire a professional plumber or contractor to handle the installation. This can significantly increase the labor costs associated with the bathroom renovation. Furthermore, the cost of specialized drill bits and other tools can add to the overall expense.

Another cost consideration is the compatibility of "no holes" vanities with different types of sinks. While it is technically possible to install a "no holes" vanity with a drop-in sink, it is generally not recommended. Drop-in sinks typically require pre-drilled holes for the faucet, which defeats the purpose of the "no holes" vanity. The ideal sink option for a "no holes" vanity is an under-mount sink, which is installed beneath the countertop. Under-mount sinks provide a clean and seamless look that complements the minimalist aesthetic of the "no holes" design.

However, under-mount sinks tend to be more expensive than drop-in sinks. Furthermore, the installation of an under-mount sink requires specialized mounting hardware and techniques. The sink must be securely attached to the underside of the countertop to prevent it from dislodging over time. This can add to the overall cost of the project.

In addition to under-mount sinks, vessel sinks are also a popular choice for "no holes" vanities. Vessel sinks sit atop the countertop and do not require any pre-drilled holes. This makes them an ideal pairing for "no holes" vanities. However, vessel sinks can also be more expensive than traditional sinks, and they may require a longer faucet spout to reach over the edge of the sink.

Ultimately, the cost implications of choosing a "no holes" bathroom vanity will depend on a variety of factors, including the chosen faucet style, the type of sink, the countertop material, and the level of professional installation assistance required. It is essential to carefully weigh these factors and create a detailed budget before making a purchase decision.

Choosing a "no holes" vanity represents a commitment to design flexibility and a willingness to navigate a potentially more complex installation process. Homeowners who prioritize aesthetic control and are comfortable with the associated challenges will find this option rewarding. Conversely, those seeking a straightforward and budget-friendly solution may find that a traditional vanity with pre-drilled holes is a more suitable choice. Careful consideration of individual needs and preferences is paramount in selecting the optimal bathroom vanity solution.

Scarabeo 5118 Sol1 89 No Hole Console Bathroom Vanity Solid Nameek S

Scarabeo 5115 Sol2 89 No Hole Console Bathroom Vanity Solid Nameek S

Scarabeo 5115 Sol2 89 No Hole Console Bathroom Vanity Solid Nameek S

Sarah 1000mm Vanity Unit In Slate Grey Inc Worktop With No Tap Holes Interiors Home S

Scarabeo 5123 49 Sol1 88 No Hole Console Bathroom Vanity Solid Nameek S

Optimus 800 Wall Hung Vanity Unit No Tap Hole Basin Matt White Wise Bathrooms

Native Trails Trough 30 Rectangle Nativestone Concrete Bathroom Sink 1 Faucet Hole Ash Nsl3019 A Rectangular Drop In Sinks

30 Nadiya Wall Mount Vessel Sink Vanity Chestnut Brown No Faucet Drillings Signature Hardware

Arenys 600mm Matt Grey Floorstanding Vanity Unit No Tap Hole Basin Wise Bathrooms

Porcelain Counter On Top Basin Vanity Sink No Tap Hole Oz Bathroom