The article must discuss elements like Materials, Construction, Finish, Hardware and Installation.

Bathroom Vanity Quality: A Comprehensive Guide

The bathroom vanity serves as a focal point in any bathroom design, offering both aesthetic appeal and essential storage functionality. Selecting a vanity that balances style with durability and long-term performance requires careful consideration of several key quality indicators. This article provides a comprehensive guide to evaluating bathroom vanity quality, focusing on materials, construction techniques, finish quality, hardware components, and installation considerations.

Materials: The Foundation of Longevity

The materials used in crafting a bathroom vanity directly impact its resistance to moisture, wear, and overall lifespan. Understanding the properties of different materials is crucial for making an informed purchasing decision.

Solid Wood: Solid wood vanities, particularly those made from hardwoods like oak, maple, or cherry, are prized for their natural beauty, strength, and durability. These vanities can withstand significant weight and are less prone to warping or sagging compared to engineered wood products. However, solid wood is vulnerable to moisture if not properly sealed and maintained. Look for vanities constructed with kiln-dried wood, which has been treated to reduce moisture content and minimize the risk of warping or cracking. Solid wood vanities often command a higher price point due to the cost of materials and craftsmanship.

Plywood: Plywood is an engineered wood product composed of multiple layers of wood veneer glued together with the grain running in alternating directions. This cross-grain construction provides excellent strength and stability, making plywood a suitable material for vanity cabinets. Marine-grade plywood, treated with water-resistant adhesives, offers enhanced protection against moisture damage. Plywood is generally more affordable than solid wood and provides a good balance of durability and cost-effectiveness.

Medium-Density Fiberboard (MDF): MDF is another engineered wood product made from wood fibers bonded together with resin under high pressure and heat. MDF has a smooth, consistent surface that is ideal for painting or applying veneers. It is less prone to warping than solid wood but is more susceptible to moisture damage. MDF is often used for vanity doors, drawer fronts, and decorative panels. Vanities constructed primarily of MDF may be less durable than those made of solid wood or plywood.

Particleboard: Particleboard is the least expensive engineered wood product, made from wood chips and resin pressed together. It is lightweight and has a relatively smooth surface, but it is also the most susceptible to moisture damage and the least durable option for vanity construction. Particleboard is often used in low-cost vanities or as a core material for laminate finishes. Avoid vanities constructed primarily of particleboard if longevity and resistance to moisture are priorities.

Other Materials: Beyond wood and engineered wood, other materials, such as stainless steel, stone, and glass, may be incorporated into vanity designs. Stainless steel vanities are highly resistant to moisture and corrosion, making them suitable for modern and minimalist bathroom styles. Stone countertops, like granite or marble, provide a luxurious and durable surface. Glass doors or shelves can add visual interest and create a sense of openness.

Construction: The Integrity of the Structure

The manner in which a bathroom vanity is constructed directly affects its structural integrity, stability, and overall longevity. Examine the joinery methods, cabinet construction, and drawer construction to assess the quality of the vanity.

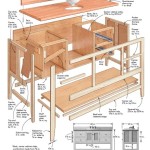

Joinery Methods: High-quality vanities utilize robust joinery methods to ensure strong and durable connections between cabinet components. Dovetail joints, characterized by interlocking wedge-shaped projections, are considered the strongest and most durable type of joinery, particularly for drawer construction. Mortise and tenon joints, involving a projecting tenon that fits into a corresponding mortise, are another durable option for connecting cabinet frames. Dowel joints, using cylindrical dowels to align and secure wood pieces, are a common and acceptable joinery method, but they may not be as strong as dovetail or mortise and tenon joints. Avoid vanities with flimsy or poorly executed joinery, as these are likely to fail over time.

Cabinet Construction: Look for vanities with solid back panels that are securely attached to the cabinet frame. A solid back panel provides structural support and prevents the cabinet from racking or twisting. The thickness of the cabinet sides and bottom also contributes to overall stability. Thicker panels are generally more durable and less prone to flexing or sagging. Examine the cabinet interiors for smooth, consistent finishes and well-aligned components. Ensure that the cabinet is level and stable when placed on a flat surface.

Drawer Construction: Drawer construction is a critical aspect of vanity quality. Dovetail joints are preferred for drawer boxes due to their strength and resistance to pulling apart. Solid wood or plywood drawer boxes are more durable than those made of particleboard or MDF. Examine the drawer glides to ensure smooth and reliable operation. Full-extension drawer glides allow for complete access to the contents of the drawer, while soft-close drawer glides prevent slamming and reduce wear and tear. Inspect the drawer bottoms to ensure they are securely fastened to the drawer box and can support a reasonable amount of weight.

Finish: Aesthetics and Protection

The finish applied to a bathroom vanity not only enhances its aesthetic appeal but also provides a protective barrier against moisture, stains, and scratches. Evaluate the quality of the finish based on its durability, smoothness, and overall appearance.

Paint: Painted vanities offer a wide range of color options and can be easily customized to match any bathroom décor. Look for vanities finished with multiple coats of high-quality paint, typically including a primer, several layers of color, and a protective topcoat. The paint should be smooth, even, and free of drips or imperfections. A durable topcoat, such as polyurethane or lacquer, provides added protection against moisture and scratches. Consider the sheen of the paint; semi-gloss or gloss finishes are more resistant to moisture and easier to clean than matte finishes.

Stain: Stained vanities highlight the natural grain and beauty of the wood. The quality of the stain is crucial for achieving a rich, even color and protecting the wood from moisture. Look for vanities with a deep penetrating stain that enhances the wood's natural character without obscuring it. The stain should be evenly applied and sealed with a protective topcoat, such as lacquer or varnish. A durable topcoat protects the stain from scratches, stains, and fading.

Veneer: Veneer is a thin layer of real wood applied over a core material, such as plywood or MDF. Veneered vanities offer the look of solid wood at a more affordable price. The quality of the veneer is important for ensuring a seamless and realistic appearance. Look for vanities with thick veneers that are securely bonded to the core material. The veneer should be free of defects, such as knots, cracks, or discoloration. The edges of the veneer should be carefully sealed to prevent moisture from penetrating the core material.

Laminate: Laminate is a synthetic material that is bonded to a core material, such as particleboard or MDF. Laminated vanities are durable, water-resistant, and easy to clean. The quality of the laminate is important for ensuring a realistic appearance and long-lasting performance. Look for vanities with thick, high-pressure laminates that are resistant to scratches, stains, and heat. The edges of the laminate should be carefully sealed to prevent moisture from penetrating the core material.

Overall Assessment: Regardless of the finish type, carefully examine the surface for any imperfections, such as scratches, dents, or inconsistencies in color or texture. Ensure that the finish is properly sealed to prevent moisture from penetrating the underlying material. Consider the ease of cleaning and maintenance when selecting a finish. Some finishes may require special cleaning products or more frequent upkeep than others.

Hardware: Functionality and Aesthetics

The hardware components of a bathroom vanity, including hinges, drawer pulls, and knobs, play a crucial role in its functionality, durability, and aesthetic appeal. High-quality hardware is essential for ensuring smooth operation, long-lasting performance, and a cohesive design.

Hinges: Hinges are responsible for the smooth and reliable operation of cabinet doors. Look for vanities with concealed hinges, which are hidden from view when the doors are closed, providing a clean and streamlined appearance. European-style hinges are typically adjustable, allowing for precise alignment of the doors. Soft-close hinges prevent slamming and reduce wear and tear on the cabinet frames. Ensure that the hinges are made of durable materials, such as steel or stainless steel, to prevent rust and corrosion.

Drawer Pulls and Knobs: Drawer pulls and knobs provide a functional and decorative element to the vanity. Choose hardware that complements the overall style of the bathroom and is comfortable to grip. Consider the material, finish, and design of the hardware to ensure a cohesive look. Solid metal hardware, such as brass, stainless steel, or chrome, is more durable than plastic or plated hardware. Ensure that the hardware is securely attached to the drawer fronts and cabinet doors.

Drawer Glides: As mentioned earlier, drawer glides are essential for the smooth and reliable operation of drawers. Full-extension drawer glides allow for complete access to the contents of the drawer, while soft-close drawer glides prevent slamming and reduce wear and tear. Look for drawer glides made of durable materials, such as steel or stainless steel, with a high weight capacity. Ensure that the drawer glides are properly installed and aligned for smooth and effortless operation.

Installation: Ensuring Proper Functionality

Proper installation is crucial for ensuring the functionality, stability, and longevity of a bathroom vanity. Even a high-quality vanity can perform poorly if it is not installed correctly. Whether hiring a professional installer or undertaking the project oneself, adhering to best practices is essential.

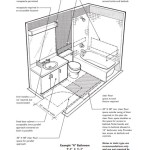

Pre-Installation Preparation: Before installing the vanity, ensure that the bathroom floor is level and that all plumbing connections are properly positioned. Shut off the water supply to the bathroom and disconnect any existing plumbing fixtures. Inspect the vanity for any damage or defects before beginning the installation process. Gather all necessary tools and materials, including a level, measuring tape, drill, screwdriver, and plumber's putty.

Installation Process: Carefully position the vanity in its designated location, ensuring that it is level and plumb. Use shims, if necessary, to adjust the height and level of the vanity. Secure the vanity to the wall studs using screws or bolts. Connect the plumbing fixtures, including the sink drain, water supply lines, and faucet. Apply plumber's putty to the drain flange to create a watertight seal. Test the plumbing connections for leaks before turning on the water supply.

Post-Installation Inspection: After installing the vanity, inspect all connections for leaks or other problems. Ensure that the doors and drawers operate smoothly and that all hardware is securely attached. Clean the vanity thoroughly and remove any debris or packing materials. Seal any gaps between the vanity and the wall or floor with caulk to prevent moisture from penetrating the cabinet.

Professional Installation: While it is possible to install a bathroom vanity oneself, hiring a professional installer is often the best option, especially for complex installations or those involving extensive plumbing work. A professional installer has the experience and expertise to ensure that the vanity is installed correctly and safely. They can also handle any unforeseen problems or complications that may arise during the installation process.

Bathroom Vanities Building Materials Southeast

Bathroom Vanities In Glendale Ca To For High Quality Vanity Unit

Luxury Bathroom Vanity Materials Finishing And Designs Make Your Stand Out

High Quality Stainless Steel Bathroom Vanity Bath Sink Cabinet China Home Made In Com

Bathroom Vanities In Glendale Ca To For High Quality Vanity Unit

Vama 60 Inch High Quality Farmhouse Barn Door Bathroom Vanity Cabinet With Double Sinks And Mirrors 536060 China Used Sliding Doors

900mm High Quality Modern Bathroom Wall Hung Vanity Unit

Bathroom Vanity Designs Blog Luxury Living Direct

York Linen Bathroom Vanity Off White Vanities

Quality Durable 24 In W X 18 D 35 H Freestanding Bath Vanity Plain Light Oak With White Resin Sink Top Re The Home Depot

Related Posts